JWE-BANSS designs, constructs and fabricates complete machines and systems engineering for slaughtering cattle – individually adapted to customer needs and as complete, turnkey system solutions on request.

As a globally operating company with decades of experience, we are familiar with all specific requirements that need to be considered in the planning of modern cattle slaughtering lines.

Therefore, our individually customized systems – regardless of the automation level – meet all requirements with regard to animal welfare, hygiene, ergonomics, occupational health and safety and environmental protection. We work with great care on the quality of our products, designing them for a long service life and the greatest possible reliability.

Since JWE-BANSS has been working closely with research and development institutions for many years, we are always able to incorporate the latest scientific findings into innovative system solutions.

1

2

3

4

5

6

7

8

9

10

1

2

3

4

5

6

7

8

9

10

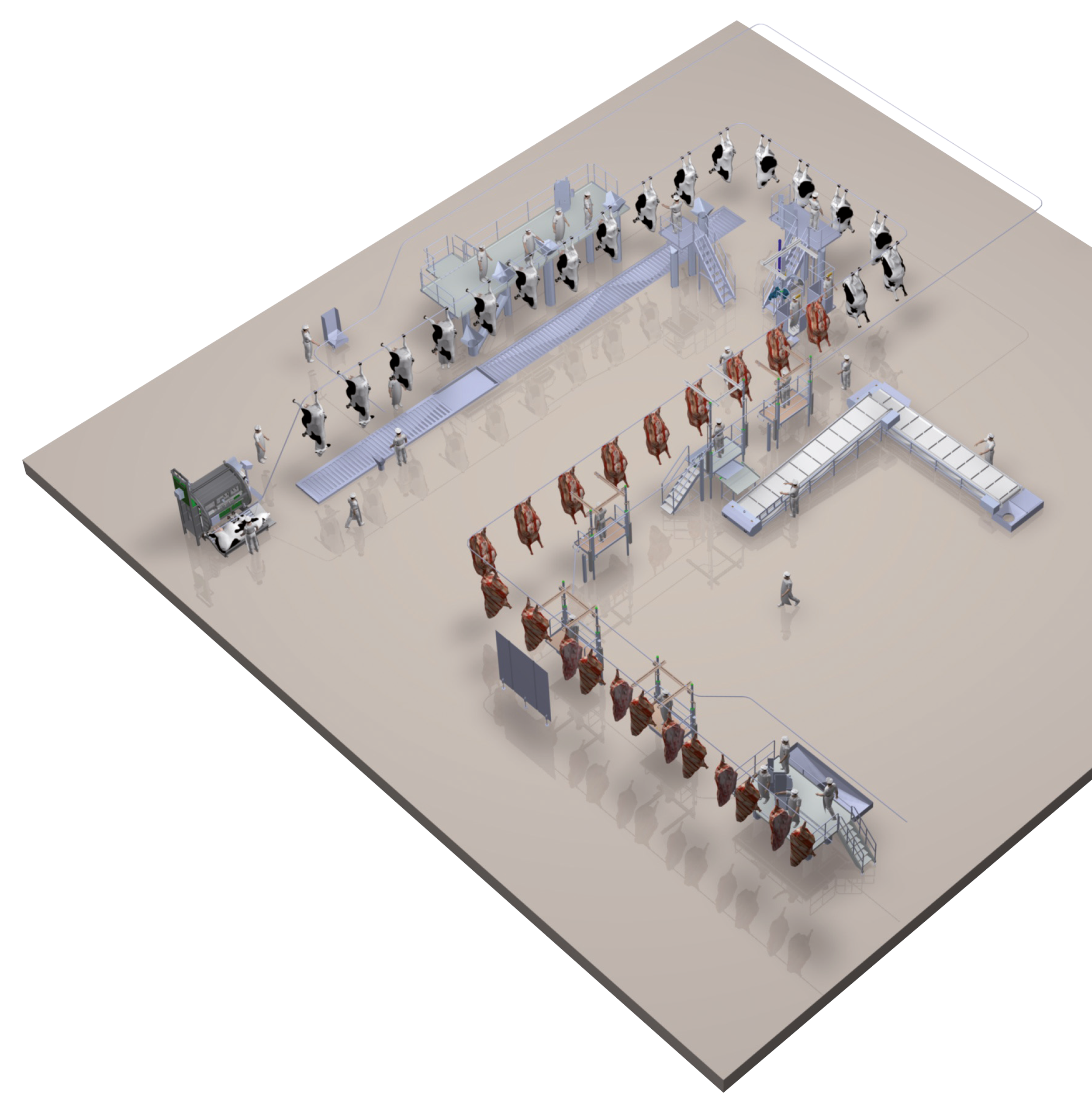

Complete Plants and Systems for Cattle Slaughtering

1. Stunning

2. Bleeding

3. Reassign pre-dehiding

4. Bung dropper

5. Dehiding

6. Paunch removal

7. Offal removal

8. Splitting

9. Trimming

10. Inspection

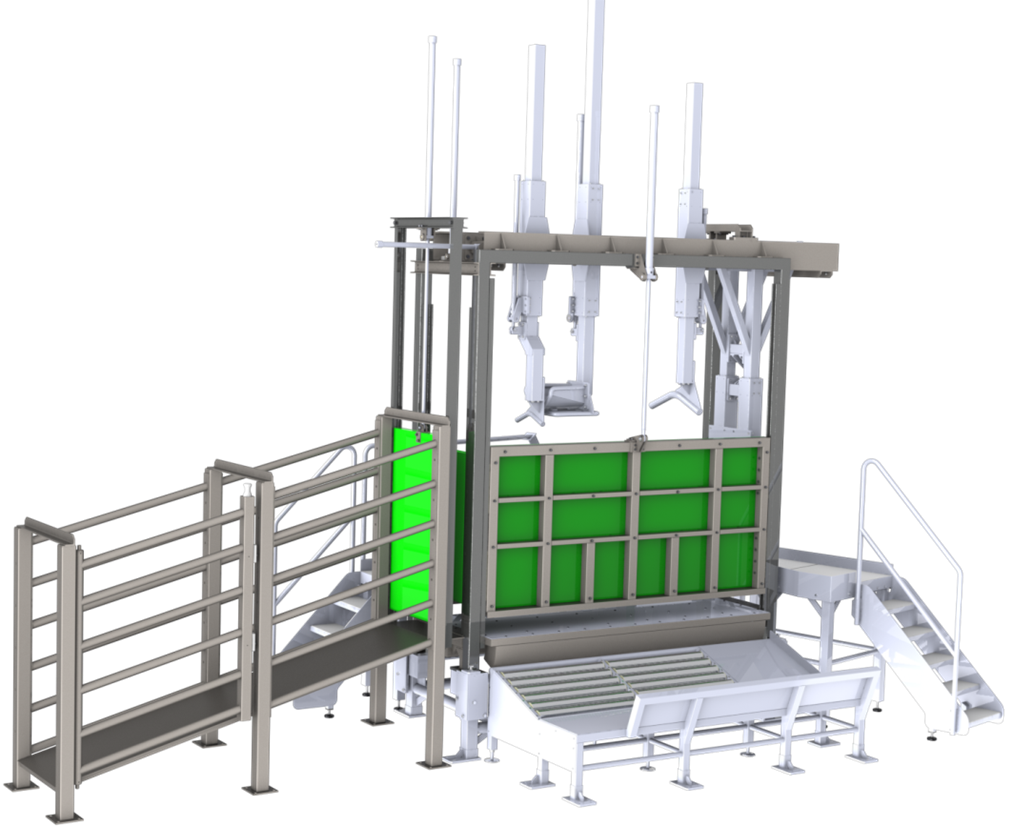

STUNNING BOX

Specifications

Stunning box designed for cattle and calves

Slaughter capacity up to 100 heads/hr

Head and neck restraint device designed with both vertical and horizontal movement

Adjustable side wall to retain calves

Robust and slip-resistant dump box floor

STUNNING BOX

Specifications

Head restrainer meets modern standards of animal welfare

With integrated double advance system

For captive bolt stunning

With hydraulic or pneumatic drive

Also available in stainless steel construction

Robust dump box floor with low noise design

WITH THE JWE-BANSS CATTLE STUNNING EQUIPMENT, THE RISK OF STUNNING FAILURE IS GREATLY MINIMIZED THROUGH THE USE OF A HEAD RESTRAINER DEVICE.

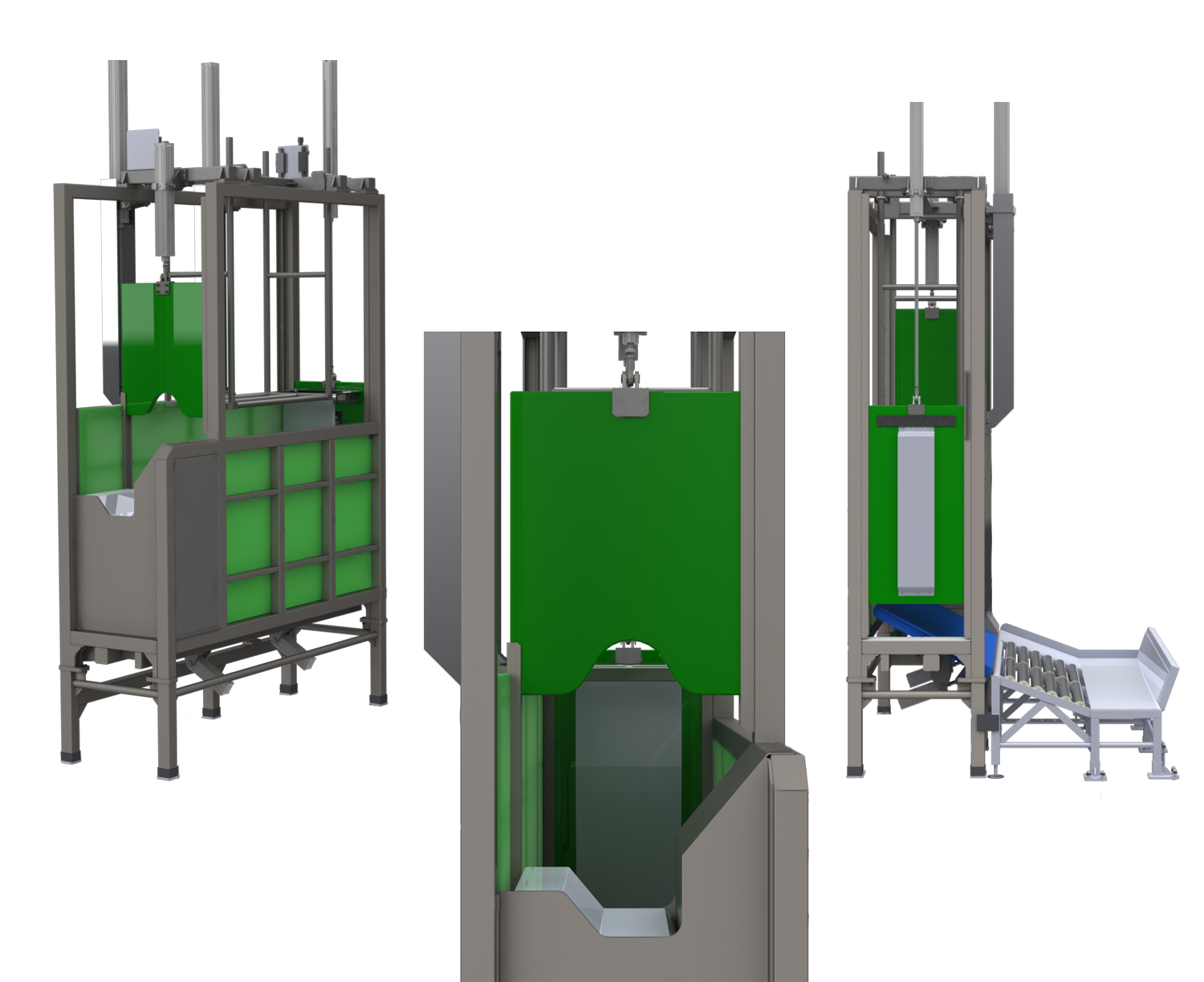

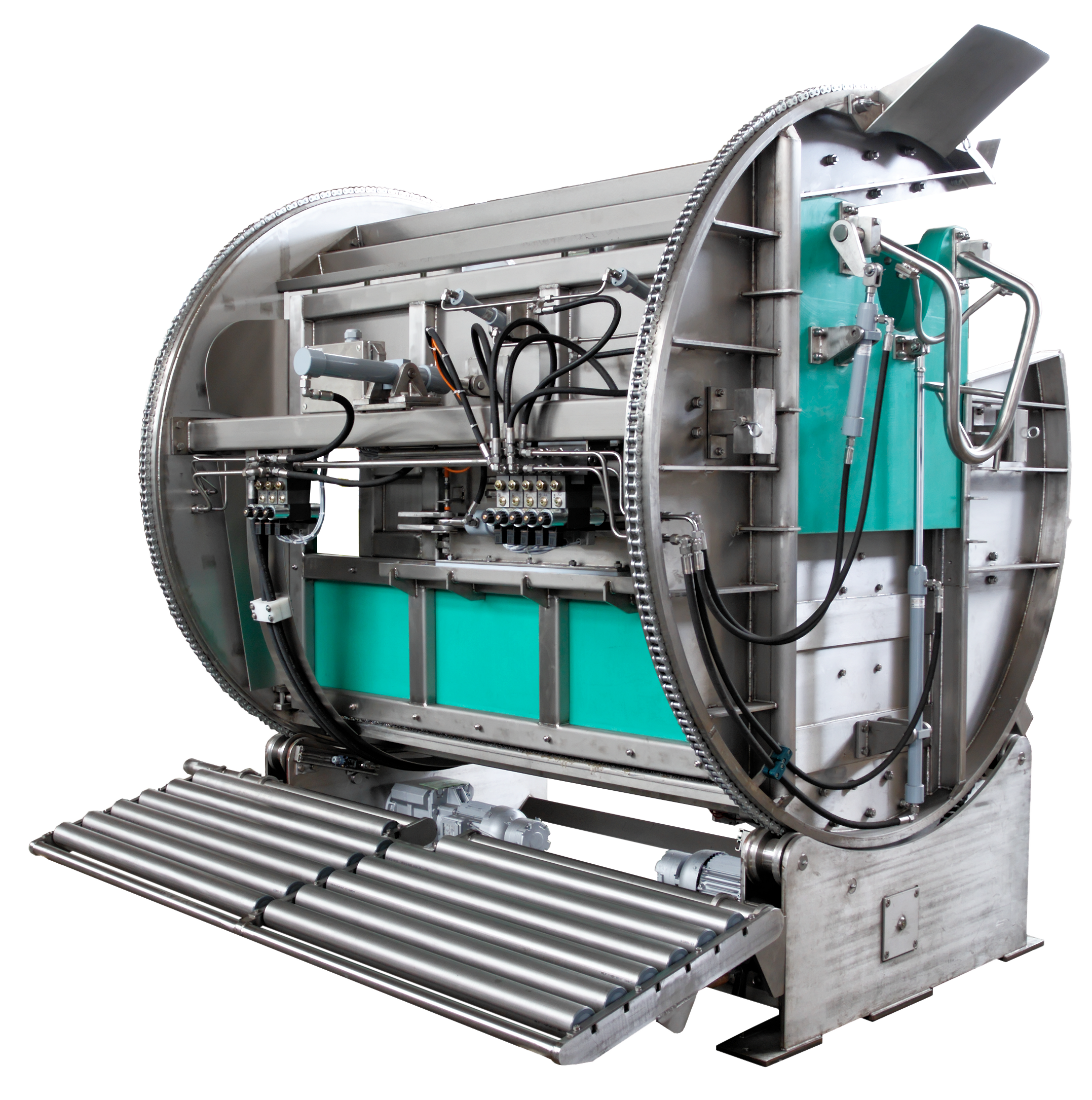

MULTIFUNCTIONAL CATTLE STUNNING BOX

Specifications

Complete stunning box can be rotated

Animal is slightly lifted and safely held by means of the breast and abdomen support

Two electrodes integrated into the neck area

Heart electrode integrated into the breast support

Head is freely accessible during the entire stunning process

Blood removal directly after the current flow has ended (sticking slide)

Gentle transfer onto a landing grid or plate conveyor

Ritual slaughter box halal slaughtering

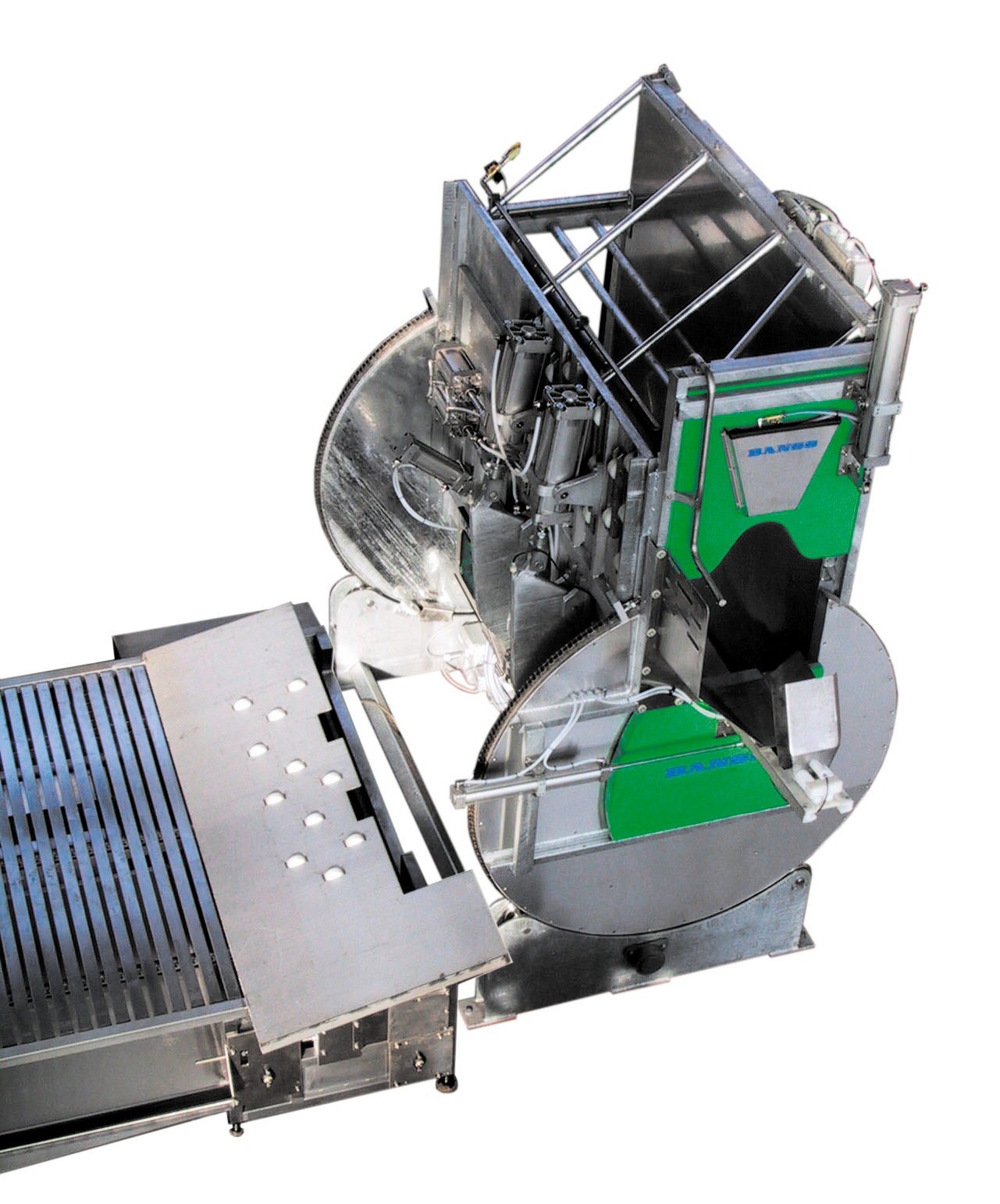

DEHIDING

E-BANSS offers our customers state-of-the-art cutting edge technology. Our dehiders for cattle, horses and calves with or without front feet shackling are suited for various installation for either continuous or non-synchronous slaughtering facilities.

| Type | Cattle/h | Hydraulic | Electro-pneumatic | Electro-hydraulic |

| Roller dehider BE3 | 75 | ■ | ■ | |

| Roller dehider BE4 | 60 | ■ | ||

| Roller dehider BE6 | 75 | ■ | ||

| Roller dehider BE5 – with swivel arm | 75 | ■ | ||

| Roller dehider BE7 | 30 | ■ |

Roller dehider BE3

Options:

Electro-pneumatic system

Electro-hydraulic system

Capacity: 75 cattle/hr (max.)

Roller dehider BE4

Options:

Hydraulic system

With shock device, without front feet shackling

Capacity: 60 cattle/hr (max.)

Roller dehider BE6

Options:

Hydraulic system

Without shock device, with front feet shackling

Capacity: 75 cattle/hr (max.)

Roller dehider BE5 – with swivel arm

Options:

Hydraulic system

Capacity: 75 cattle/hr (max.)

Roller dehider BE7

Options:

Electro-pneumatic system

Capacity: 30 cattle/hr (max.)